Flying Concrete

Flying Concrete

Flying Concrete

Flying Concrete

Cob Code?

Cob Code?

Glass Cob

Glass Cob

Tool: Bondo Spreader

Tool: Bondo Spreader

McCabe’s Cob Castle

McCabe’s Cob Castle

Chopped Straw

Chopped Straw

Innovative Rocket Stove Designs

Innovative Rocket Stove Designs

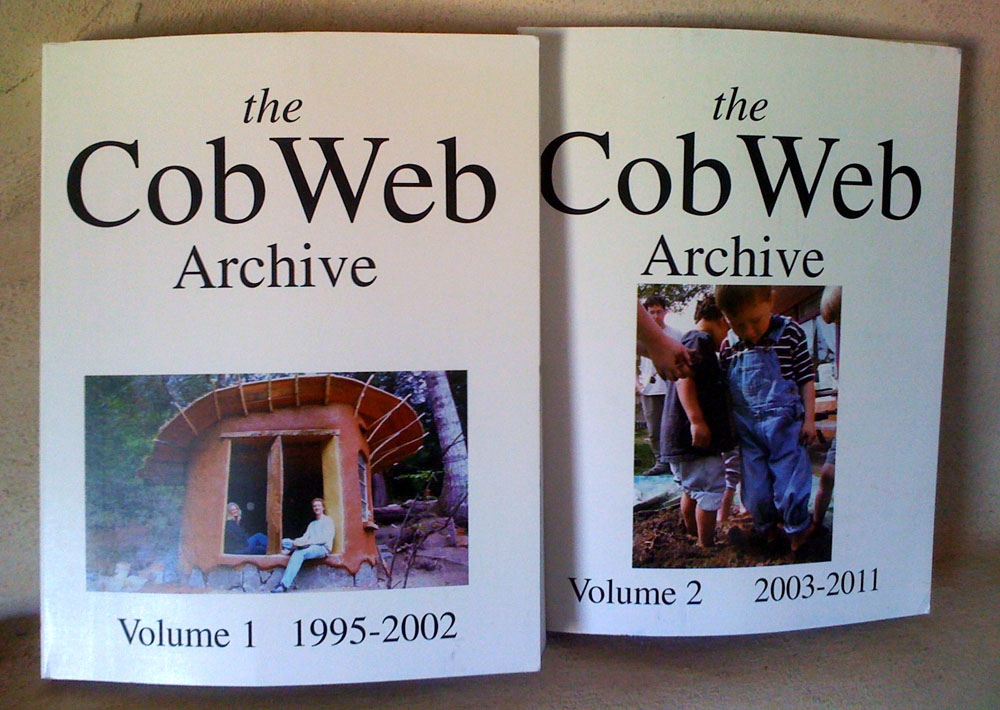

The CobWeb Archives

The CobWeb Archives

Trombe Wall

Trombe Wall

Zuker’s Medieval Cottage

Zuker’s Medieval Cottage

Milkwood Hot Water Rocket Stove

Milkwood Hot Water Rocket Stove

BobCob

BobCob

Walipini: A Place of Warmth

Walipini: A Place of Warmth

Texas Natural Builders Pallet House

Texas Natural Builders Pallet House

Cob Dwellings Code: Devon Earth Association

Cob Dwellings Code: Devon Earth Association

Traditional Adobe Hogan

Traditional Adobe Hogan

Making Wheat Paste

Making Wheat Paste

Mud Cookies

Mud Cookies

Watts Towers

Watts Towers

Clay Culture

Clay Culture

Making Cob with a Auger Mixer?

Making Cob with a Auger Mixer?

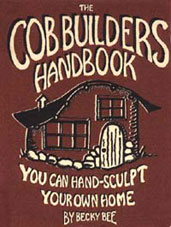

The Cob Builders Handbook

The Cob Builders Handbook

AdobeUSA 2009 Photos

AdobeUSA 2009 Photos

Diva Cob Oven

Diva Cob Oven

Solunit Rocket

Solunit Rocket

The Dome by Carole Crews

The Dome by Carole Crews

The Cob Mob Rocket

The Cob Mob Rocket

Kindra’s Mountain Cottage

Kindra’s Mountain Cottage

Portland Hostel

Portland Hostel

Electric Mixer Cob

Electric Mixer Cob

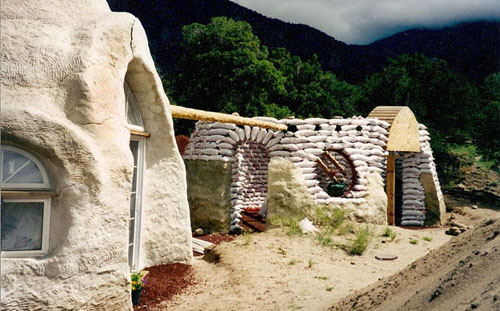

Earthbag Slideshow

Earthbag Slideshow

Mesa Dirt

Mesa Dirt

Book: Using Natural Finishes

Book: Using Natural Finishes

Fruth and Brown Cob House

Fruth and Brown Cob House

Rocket Stove Experimenters Corner

Rocket Stove Experimenters Corner

Eco-sense Cob House

Eco-sense Cob House

Cob Oven Video

Cob Oven Video

Crews & Lawyer Mural

Crews & Lawyer Mural